Using spray equipment to limit drift and maximise coverage

Figure 10. Spraying at Katherine Research Station

Weather conditions in the NT can be detrimental to achieving good spray outcomes. There are ways to maximise the chance off chemical reaching the target by spray rig setup and selecting appropriate nozzles.

Boom height

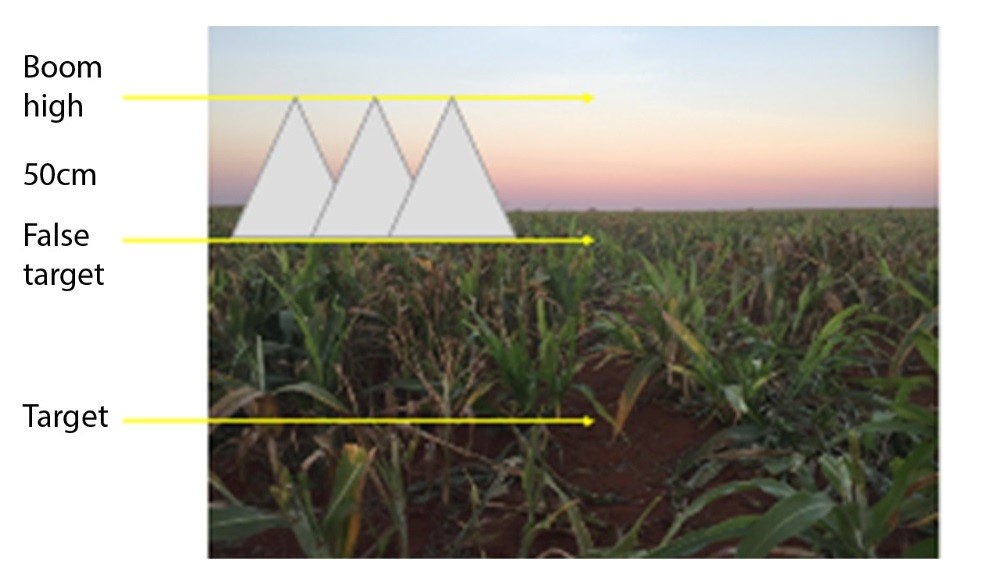

It is important to set the boom high enough that there is overlap of nozzle fans but not too high that there is potential drift. Figure 3 shows that 110 degree flat fan Nozzles should be 50cm from the target. If there is a false target, which may be stubble or crop. The boom should be 50 cm above that. Grains Research and Development Corporation (GRDC) data suggests that raising the boom from 50cm to 75cm increases drift potential four times. Counteract this risk by increasing droplet size to reduce driftable fine droplets. This will also improve coverage as larger droplets will have greater velocity and will get through the crop/stubble canopy.

Speed

Figure 11. Selecting boom height when there is a false target.

Increasing speed reduces the time it takes to spray a paddock which can be beneficial when trying to get a job done before weather conditions change. Unfortunately increasing speed can lead to wind shear and eddies, which creates increased fine droplets. Increased speed without increasing water rate can decrease coverage, particularly with a standing target.

Water rate

Increasing water rate is the easiest way to increase coverage. If course droplets need to be used for drift reduction, increasing water rate can significantly reduce the issue of poor coverage generally associated with increased droplet size. Water rate can be increased without decreasing speed, if you have the correct nozzle.

Nozzle selection

There are many different nozzles but for broadacre boom spraying, the main groups used are conventional flat fan nozzles, pre-orifice flat fan nozzles and air induction nozzles. Characteristics of these nozzles can be seen in table 2.

Figure 12.Assorted nozzle heads.

Conventional nozzles | Pre-orifice flat fan nozzles | Air induction nozzles |

|---|---|---|

|

| Agritop AirMix Flat Fan

|

|  |  |

The pre orifice meters flow and restricts the amount of liquid which decreases internal pressure. This leads to larger droplets. The difference with air induction is that they contain a venturi which draws air bubbles into the liquid stream. The droplets exiting the nozzle are generally course to very cause and are filled with air. This can create a cushioning effect when they hit the plant so they don’t bounce off, which can happen with large droplets from conventional nozzles.

Colours of the nozzle represent its size of the nozzle e.g. all yellow nozzles are 02 (0.2 gallons per min @ 2.8bar). The larger the nozzle, the more water it puts out. All nozzle manufacturers have charts for their nozzles. A nozzle chart allows the user to pick the appropriate nozzle for the water rate, speed and pressure the want to use.

Application technology workshops

The Department of Primary Industries and Resources and NT Farmers identified the need for greater training in application technology and applied for funding from Federal Government’s National Landcare programme promoting sustainable agriculture. This funding was used to run training workshops at Douglas Daly, Katherine and Darwin. A YouTube video was also produced to demonstrate nozzle selection.

If you would like further information about improving your application practices or would like staff within your organisation to attend a spray technology workshop, please contact Callen Thompson callen.thompson@nt.gov.au

Give feedback about this page.

Share this page:

URL copied!